Started in 2006:

prototyping parts machining factory

Prototype parts machining rapid manufacturer

- Samples in 3 day, with $50-200 sample fee 100% refunded on bulk orders (100+ pieces)

- Quality Risk-Free Guarantee- 100% refund or rework within 48 hours, including shipping

- AI+20 engineers review DFM and optimize in advance, reducing part costs and risks by more than 30%

- 12 quality control procedures, product yield can reach more than 99.98%

With 19 years of CNC prototyping machining experience, we have successfully produced over 20,000 precision parts for various industries.

We have more than 6 professional project engineers and a standard algorithm system, and we can complete your DMF evaluation and quotation within 2 hours.

We have 15 quality engineers and 12 strict quality control processes, using advanced testing equipment and preventive measures to ensure accuracy at every step.

Trusted by Global Industry Leaders

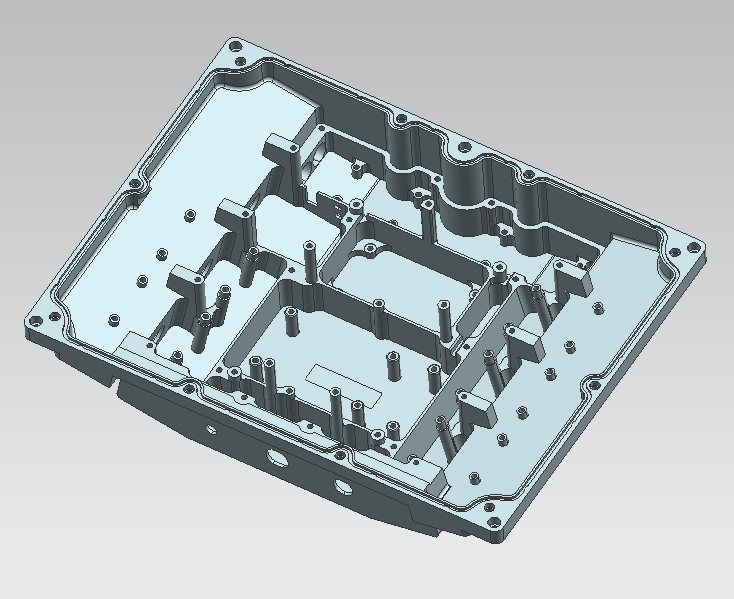

Our Custom CNC Prototype Products

We specialize in manufacturing high-quality metal and plastic prototypes, ensuring exceptional accuracy and craftsmanship in every project. Here are some examples of CNC-machined prototype parts we’ve produced for our customers, shared with their permission. With expertise in high-precision CNC machining, we have successfully delivered over 20,000 unique models.

Our Custom Rapid CNC Prototyping Machining Services

We provide professional rapid CNC prototyping and manufacturing solutions for a wide range of industries, handling even the most complex projects with ease. Backed by an experienced and dedicated project team, we ensure seamless support from start to finish. Our high-quality, precise, and efficient CNC prototyping services are designed to bring your ideas to life and accelerate their journey to market.

CNC Milling

- 1. Achieves +/- 0.0002 in. precision.

- 2. Quick milling services.

- 3. Custom milled parts for prototyping and production.

CNC Turning

- 1. Delivers precision of +/- 0.0002 in.

- 2. Fast-turnaround CNC turning services.

- 3. Custom turned parts for prototyping and production.

5-Axis CNC Machining

- 1. Precision tolerances up to +/- 0.0003 inches.

- 2. Fast machining services.

- 3. Custom mechanical parts for prototypes and production.

Custom Your CNC Prototype Machining Products

From Concept to Mass Production: End-to-End Customization for CNC Prototype Machining Products

- Send Your CAD File

Send your project information through the quote page. All files support NDA.

- Quotation and DFM Analysis

We will send back the design for manufacturability analysis and real-time quotation within 12 hours.

- Start Production

Once the order is confirmed, we will start the manufacturing process using your CAD design.

- Receive Your CNC Prototype Machining Products

We will send tracking information after the goods are sent, so our customers can understand well that where and when the goods can be arrived.

Start your CNC machining prototype project today !

Why Choose VMT for Your Project

With over 100 advanced CNC machines, an in-house rapid prototyping team, and fast-turnaround custom CNC machining, VMT offers diverse material and finishing options to meet your project needs.

Our Production Environment

Choose VMT for high-precision CNC prototype machining – Direct from Our Factory for Better Prices and Higher Profits! With advanced CNC technology and advanced inspection equipment, we ensure precision at every stage.

12-Step Quality Inspection Process

With a dedicated quality control management team and advanced high-precision testing equipment, we oversee every step from raw materials to shipment with thorough follow-up testing and real-time transparency. This rigorous process ensures a 98% product yield rate, delivering exceptional quality and reliability.

DFM Analysis

Size Recognition

Materials Testing

CNC Prototyping and Machining

IPQC/FQC

SPC/CPK

Problem Found

Problem Solving

OQC

Surface Finishing

Full Inspection

Package

Customized Prototype Parts Materials

Selecting the right material for a project depends on multiple factors, with a key principle being that the material’s performance must meet both the product’s technical specifications and environmental requirements. At VMT, we carefully evaluate application needs to choose the most suitable material, ensuring the optimal realization of your design and the highest product quality.

We collaborate with long-term material suppliers to source SGS-certified materials and work with experienced surface finishing manufacturers with over 10 years of expertise to offer more than 40 finishing options. Our dedicated supplier quality engineer monitors the entire finishing process on-site, ensuring 100 percent inspection of product appearance and strict quality assurance.

Metal Materials

- Aluminum

- Stainless steel

- Copper

- Brass

- Titanium

- Steel, etc.

Plastics Materials

- PEEK

- Acrylic

- POM

- ABS

- Nylon

- PE, etc.

Customer Visit Factory + Exhibitions

We cordially invite customers from around the globe to visit our factory, Shenzhen VMT Metal Product Co., Ltd., located at Building 14, Dawei Shahe Industrial Zone B2, Xinzhuang Community, Matian, Guangming, Shenzhen, China.

Successful Cases CNC Prototype Machining Project

Recently, Mr. Wang, a procurement manager, found our VMT website through the keyword “aluminum alloy precision prototype”. His company was developing a new energy product and urgently needed a high-precision aluminum alloy component.

Rapid CNC Prototyping: Delivering High-Precision Aluminum Parts in Just 1 Days

After signing an NDA, Mr. Wang shared the 3D drawings with us. Our engineer, Mr. Fan, immediately reviewed the design and completed the quotation, production plan, and delivery schedule within one hour. Due to confidentiality, product images are not displayed.

Mr. Wang explained that his previous supplier failed to meet tolerance requirements, widening the tolerance from ±0.01mm to ±0.05mm, causing assembly issues. After an in-depth technical discussion, our engineers identified the processing errors in the previous supplier’s approach. VMT specializes in precision CNC machining, achieving ±0.01mm tolerance.

With over 60 advanced 4/5-axis CNC machines and a dedicated aluminum prototype team, we quickly accommodated his urgent order. Production was completed within a day, and we even pre-tested the assembled components to ensure seamless integration.

A few months ago, a new medical industry customer provided us with high tolerance drawings for a prototype. The design looked simple, but its precision was very high.

High Precision CNC Machining of Medical Parts

Quality control is critical in CNC machining, especially for the medical industry, where precision can directly impact performance and safety. At VMT, we utilize advanced measurement machines and inspection tools to ensure every CNC-machined component meets strict tolerance requirements.

Our expert team, state-of-the-art CNC machines, and high-precision prototyping capabilities allow us to consistently meet ±0.01mm tolerances, even for the most demanding medical applications.

With 15+ years of experience and a dedicated rapid prototyping team, VMT delivers high-precision, small-batch CNC parts with fast turnaround times.

When searching for an aluminum alloy CNC machining factory, many prefer large-scale manufacturers due to their advanced equipment, superior quality, and reliable delivery times. However, with so many CNC machining factories available—each with different strengths and specialties—how do you choose the right one?

Precision, Quality, and Reliable Service

At VMT, we have been focusing on high-precision aluminum parts, enclosure machining, and quality surface finishing for over 15 years. Our team includes six engineers with more than 20 years of CNC machining experience and two surface treatment specialists. This helps us deliver stable quality and reliable results.

We now work with customers in 62 countries, including well-known brands and industry leaders like Volkswagen, Ford, Haas, BELL, and GE. You can count on us for precision, quality, and trusted service.

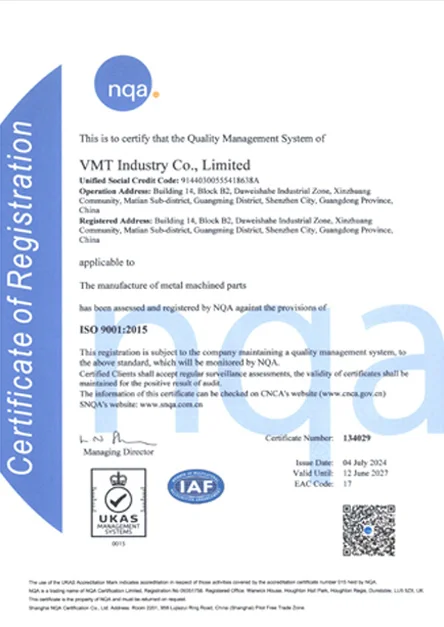

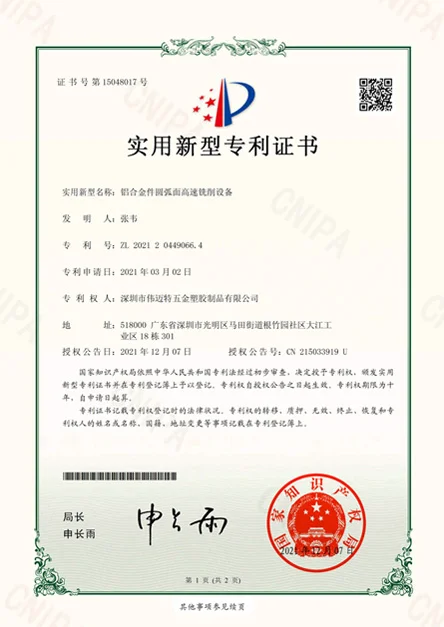

Our Certificate

As a seasoned manufacturer specializing in on-demand CNC prototype machining, VMT is certified in the ISO 9001:2015 Quality Management System and IATF 16949. This ensures that all departments adhere rigorously to these standards for strict production control.

IS0 9001

IATF 16949

SGS

Composite Machining

Aluminum Milling Patent

Frequently Asked Questions About CNC Prototype Machining

VMT is proficient in facilitating the production and prototyping of large machined parts, be it metal or plastic. We boast a substantial CNC machining build envelope measuring 2000 mm x 1500 mm x 300 mm. This ensures we can accommodate even sizable parts, including those tailored for furniture or architectural applications.

We use an advanced quality control system, equipped with manual and automated inspection equipment. All reports are archived and kept for two years, such as first article inspection, process inspection, and shipment inspection. From raw materials, CNC prototyping machining to shipment, We have dedicated personnel to follow up and share progress in real time. We have a testing laboratory equipped 2D projector, 3D projector and other high-precision testing instruments.

We all use new and standard materials, not secondary recycled materials. Our material composition is standard and we can provide third-party test reports from SGS, CTI, TUV, etc. Please see the attachment.

We have a testing laboratory equipped with three-dimensional, two-dimensional, projectors and other high-precision testing instruments.

At present, VMT is equipped with two processing teams specializing in small batches or samples, which can complete the samples in 24 hours at the earliest, to better serve customers in the early verification stage. At the same time, VMT has 100 devices, which run 24 hours a day to meet the fast delivery requirements of customers. In addition, VMT has a stable outsourcing supplier who has cooperated with us for more than 10 years to assist in fast shipment of samples and large batches. If there is an unexpected delay in delivery, we can bear the relevant costs according to customer requirements.

Trust us with your project. If the quality doesn’t meet your requirements, we’ll refund you within 24 hours.

We ensure top quality with precise 3D/2D project validation, height/thread/roughness gauges, and full-dimension inspection reports.

Contact us for a free quote

Share your requirements, drawings, and reference images with us. Get a free prototype machining quote and bring your idea to life with precision and quality.

- Address: Building 14, DaweiShahe Industrial Zone B2, Xinzhuang Community, Matian, Guangming, Shenzhen, China

- Tel: 86-150-9991-1516